Mastering Surface Film Conditions in Abaqus for High-Fidelity Simulations

Introduction: The Critical Role of Surface Film in Abaqus Modeling

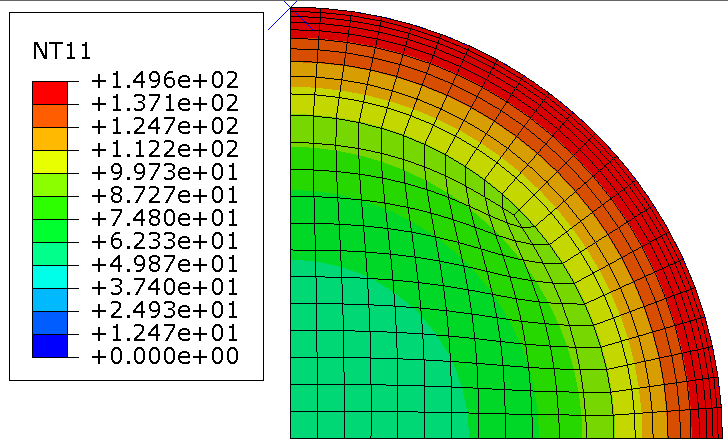

In the realm of finite element analysis, particularly when dealing with thermal and coupled thermal-mechanical problems, the accurate representation of heat exchange between a solid surface and a surrounding fluid is paramount. Abaqus, a leading FEA software, provides a powerful tool for this purpose: the surface film condition. This boundary condition allows engineers and researchers to meticulously define the convective heat transfer occurring at the interface between a solid body and a moving fluid. Understanding and correctly implementing surface film conditions is not merely a procedural step; it is a fundamental aspect that directly influences the fidelity and reliability of simulation results. This comprehensive guide will delve deep into the intricacies of surface film conditions within Abaqus, exploring its underlying principles, various parameters, application scenarios, and advanced considerations.

Fundamentals of Convective Heat Transfer and the Surface Film Coefficient

At its core, the surface film condition in Abaqus aims to model convective heat transfer, a mechanism of heat transfer that occurs due to the movement of fluids (liquids or gases). This movement facilitates the transfer of thermal energy between a surface and the fluid in contact with it. The rate of convective heat transfer is governed by Newton's Law of Cooling, which states that the heat flux ($q$) is directly proportional to the temperature difference ($\Delta T$) between the surface ($T_s$) and the bulk fluid ($T_f$), and the proportionality constant is the surface film coefficient ($h$):

$$\mathbf{q = h(T_s - T_f)}$$

The surface film coefficient, often referred to as the convection coefficient or the heat transfer coefficient, is not a material property but rather a parameter that depends on a multitude of factors, including the fluid properties (density, viscosity, thermal conductivity, specific heat), the flow velocity, the geometry of the surface, and the nature of the flow (laminar or turbulent). Therefore, accurately determining or estimating the surface film coefficient is crucial for obtaining meaningful simulation results in Abaqus.

Defining Surface Film Conditions in Abaqus: A Step-by-Step Approach

Abaqus offers a flexible framework for defining surface film conditions, typically applied as a boundary condition to the exposed surfaces of a solid part within an assembly. The process generally involves the following steps:

- Surface Selection: The first step is to precisely select the surfaces on which the convective heat transfer is to be modeled. This is usually done through the Abaqus/CAE interface by selecting the desired faces of the part instance in the assembly.

- Boundary Condition Definition: Navigate to the boundary condition creation dialog box. In the thermal category (or thermal-electrical category for coupled analyses), choose the "Film condition" type.

- Magnitude Specification: This is where the crucial parameters of the surface film condition are defined. Abaqus allows for various ways to specify the surface film coefficient and the sink temperature (the bulk fluid temperature):

- Constant Film Coefficient and Sink Temperature: The simplest approach involves defining constant values for both the surface film coefficient ($h$) and the sink temperature ($T_{sink}$). This is suitable for scenarios where these parameters are relatively uniform and do not vary significantly over the surface or time.

- Varying Film Coefficient and/or Sink Temperature with Field: Abaqus allows for the surface film coefficient and/or the sink temperature to be defined as a function of position using predefined fields. This is particularly useful when dealing with non-uniform flow conditions or spatially varying fluid temperatures. The field can be defined based on nodal coordinates, element centroids, or other solution-dependent variables from a previous analysis.

- User-Defined Film Coefficient (User Subroutine): For complex scenarios where the surface film coefficient depends on factors not directly available as standard Abaqus field variables (e.g., local flow velocity obtained from a coupled fluid flow simulation), users can employ a user subroutine (e.g., `HETVAL` in Abaqus/Standard or `VUHET` in Abaqus/Explicit) to define the coefficient. This provides maximum flexibility in modeling intricate convective heat transfer phenomena.

- Dependence on Surface Temperature: In some cases, the surface film coefficient itself might be dependent on the surface temperature. Abaqus allows for defining this dependency through tabular data.

- Distribution and Region: Ensure that the defined surface film condition is applied to the correct geometric region (the selected surfaces). The distribution option allows for uniform or non-uniform application based on the chosen magnitude specification method.

- Time Dependence: For transient thermal analyses, the surface film coefficient and/or the sink temperature can be defined as time-dependent using tabular data or user subroutines, allowing for the simulation of time-varying convective conditions.

Advanced Considerations and Best Practices for Surface Film Modeling

While the basic application of surface film conditions in Abaqus is straightforward, achieving accurate and reliable results often requires careful consideration of several advanced aspects:

- Accurate Estimation of the Surface Film Coefficient: The accuracy of the simulation is heavily reliant on the appropriate value of the surface film coefficient. This often necessitates the use of empirical correlations derived from experimental data or computational fluid dynamics (CFD) analyses. Numerous correlations exist in heat transfer literature for various flow regimes (laminar, turbulent, natural convection, forced convection) and geometries. Selecting the correct correlation is crucial.

- Spatial Variation of the Film Coefficient: In many real-world scenarios, the surface film coefficient is not uniform across the entire surface. Factors such as flow separation, stagnation points, and developing boundary layers can lead to significant spatial variations. Utilizing field-dependent definitions or user subroutines can capture these variations more accurately.

- Transient Effects: In transient thermal analyses, the surface film coefficient and the sink temperature might change over time due to variations in the fluid flow or the bulk fluid temperature. Defining these parameters as time-dependent is essential for capturing these dynamic effects.

- Coupled Thermal-Fluid Analysis: For problems involving strong interaction between the thermal behavior of the solid and the fluid flow, a one-way or two-way coupled thermal-fluid analysis using Abaqus and a CFD solver (or Abaqus's own CFD capabilities if applicable) might be necessary. In such cases, the surface film coefficient can be derived from the fluid flow solution and applied to the solid surfaces in Abaqus.

- Radiation Effects: In high-temperature applications, radiative heat transfer might be significant and should be considered in addition to convection. Abaqus allows for the definition of surface radiation conditions, which can be combined with surface film conditions to provide a more complete thermal boundary condition.

- Mesh Refinement: The accuracy of the surface film condition application can also be influenced by the mesh discretization near the fluid-solid interface. Sufficient mesh refinement in these regions can help to accurately capture the temperature gradients and the effects of convection.

- Validation and Verification: It is always recommended to validate the simulation results against experimental data or analytical solutions whenever possible to ensure the accuracy of the surface film modeling approach.

Illustrative Examples of Surface Film Condition Applications in Abaqus

The versatility of the surface film condition in Abaqus allows it to be applied to a wide range of engineering problems, including:

- Cooling of electronic components: Modeling the heat dissipation from electronic devices through forced or natural convection to the surrounding air.

- Heat exchangers: Simulating the heat transfer between two fluids separated by a solid wall, where surface film conditions are applied to both fluid-solid interfaces.

- Thermal management in automotive applications: Analyzing the heat transfer from engine components to the cooling fluid or the surrounding air.

- Building thermal analysis: Modeling the convective heat transfer between the interior and exterior surfaces of a building and the surrounding air.

- Aerospace engineering: Simulating the aerodynamic heating of aircraft surfaces due to air friction.

- Industrial processes: Analyzing heat transfer in furnaces, ovens, and other thermal processing equipment.

Conclusion: Harnessing the Power of Surface Film Conditions in Abaqus

The surface film condition in Abaqus is an indispensable tool for accurately modeling convective heat transfer in a wide array of engineering applications. By understanding the fundamental principles of convection, carefully defining the relevant parameters (including the surface film coefficient and the sink temperature), and considering advanced aspects such as spatial and temporal variations, users can leverage the full power of Abaqus to obtain high-fidelity simulation results. Whether dealing with simple constant convection or complex user-defined heat transfer scenarios, a thorough understanding of surface film conditions is crucial for making informed engineering decisions and designing efficient thermal systems. Mastering this boundary condition empowers engineers and researchers to unlock deeper insights into the thermal behavior of their designs and achieve unparalleled accuracy in their finite element analyses. The ability to accurately represent the interaction between solids and fluids through the surface film is a cornerstone of advanced simulation, enabling the prediction and optimization of thermal performance across diverse industries. By paying close attention to the nuances of defining and applying these conditions, users can significantly enhance the reliability and predictive capability of their Abaqus models.

Comments

Post a Comment